Forklift attachment is the equipment installed on the forklift and used with the forklift. It can be clamps, forks, push-pull devices, etc., which can be replaced according to different working conditions and usage requirements to realize the multi-purpose of forklift trucks. Due to the characteristics of high productivity, low operating cost, safe and reliable operation, it is widely used in paper making, packaging, printing, petroleum, chemical, electronics, beverage, warehousing, tobacco and other industries, and is a highly efficient equipment for automated loading and unloading, stacking and handling.

I. The common genus has:

It can be rotated 360 degrees, used for turning goods and emptying containers, tipping goods over or placing vertical goods horizontally. It can be connected with other attachments to make the attachments have the function of rotation.

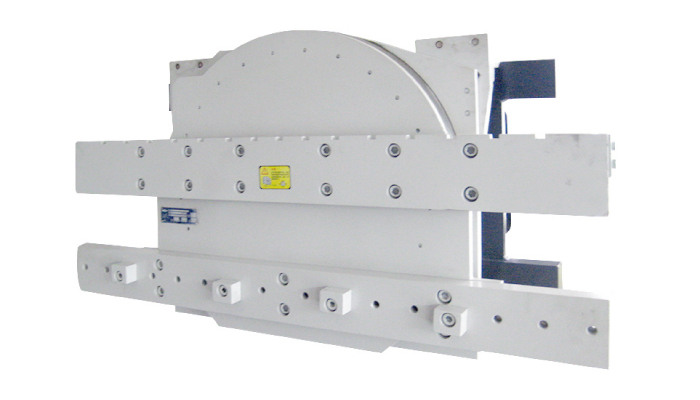

A tool used for handling goods placed on skids to realize efficient handling and stacking operations. Its main purpose is to increase the efficiency of handling bagged goods (e.g. fertilizers, cement, etc.) and boxed goods (e.g. cloth, cosmetics, etc.), and to reduce the cost of pallets. Push-pullers reduce the use of pallets and enable palletless operations.

lBucket Clamps:

Mainly used for oil drums or other barrel handling and tipping;.

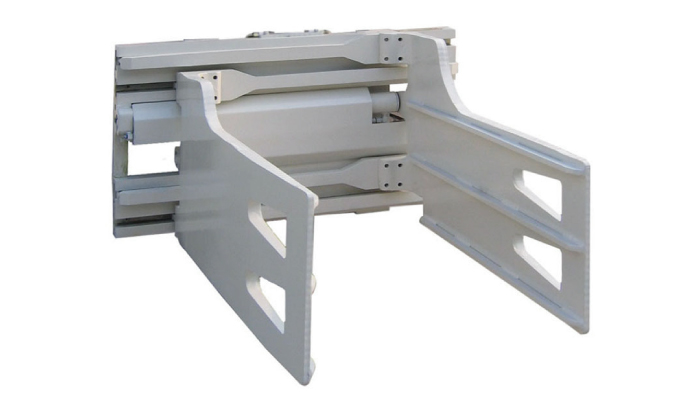

Applied for handling various forms of soft bale goods, such as rags, waste paper, cotton, wool, hay, industrial scraps and other soft bale goods. Efficient and economical handling and stacking operations without pallets.

Applicable to warehousing, home appliances, electronics and other industries, need to use cartons to pack goods without pallet handling and stacking operations.

Widely used in paper, carton, printing, trade, packaging and other round objects loading and unloading and handling;

Hydraulically adjust the fork spacing to realize the handling of different specifications of pallets of goods; no need for operators to manually adjust the fork spacing. Reduce the labor intensity of the operator

II. Precautions for the use of forklift attachments

Attachments are mostly composed of short piston hydraulic cylinders, high-pressure hoses, hose rewinders, quick couplings, round seals, special attachments, etc. These parts can be cleaned and maintained with reference to general hydraulic parts. These parts can refer to the general hydraulic parts for cleaning, maintenance.

In addition to pay attention to the pipeline system of oil seepage, rupture and other anomalies in the use of attachments, especially the permissible load of attachments, lifting height, the size of the goods and the scope of application of the attachments, the width of the operation, should be strictly in accordance with the performance of the performance of attachments parameter table, neither overloading, nor partial loading.

In the use of forklift trucks, the fork thickness and fork length of the two forks should be roughly equal. And after the two forks are mounted on the forklift, their upper horizontal surfaces should be kept in the same plane. Must strictly comply with the operating procedures, do not allow overloading or long-distance handling of goods; in the handling of long or center of gravity position can not be determined when the object, there should be a person to direct, and be extra careful. When using forks, the fork distance should be suitable for the width of the load, the forks should be inserted as deeply as possible under the load, and the load should be stabilized with the smallest backward tilt of the gantry to prevent the load from sliding backward, and the gantry can be tilted forward a little bit when the load is put down in order to put down the goods and pull out the forks safely.

Operation, the fork should be as low as possible in the form of speed, to 30 ~ 40mm from the ground is appropriate, the gantry should be appropriate tilt back, driving shall not arbitrarily elevate or lower the fork, shall not be turned on the ramp and driving across the slope, not allowed to use the fork to pick over the pallet of the method of unloading; forks are not permitted to use the fork to shovel directly to transport hazardous and flammable goods, etc.; not permitted to use the single-fork operation or inertial force of forked goods; moreover, shall not be used for braking inertia to put the rounded or easily rolling goods.

Service Hotline:+86-17350015962/+86-0592-5681408

Service Hotline:+86-17350015962/+86-0592-5681408